The AZ telescope mount is loose? Teach you how to diagnose and repair the problem step by step!

The AZ telescope mount is loose? Teach you how to diagnose and repair the problem step by step!

The stability of the az-mount of the telescope directly affects the observation experience, but long-term use or transportation vibration may cause looseness, making the pointing inaccurate and the tracking unstable. This article will take SVbony SV225 telescope mount as an example to introduce in detail the common causes of telescope mount looseness, and provide detailed repair plans to help you restore the accuracy of the equipment.

Common problems and solutions for telescope mount looseness

Loosening of the pitch axis or azimuth axis screws (there is a clear gap or "click" sound in a certain direction when the telescope is gently pushed)

After long-term use, the locking nut of the fixed axis axial assembly loosens, causing shaking in the up and down (pitch) or left and right (azimuth) directions.

Solve the problem of loose nuts

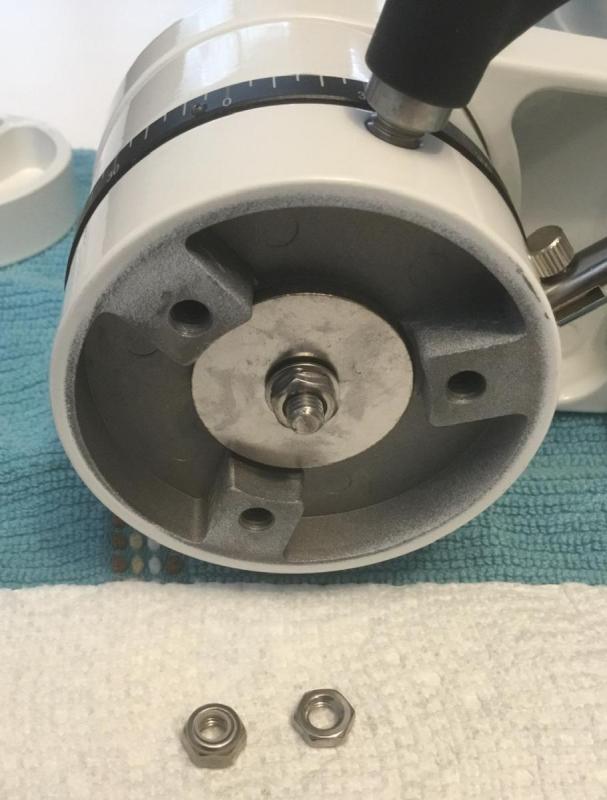

First, remove the three Allen screws to expose the unsuitable nylon locking nut under the tripod mounting plate.

Then remove the old lock nut and the washer underneath.

Remove the adjustment collar and clean it of burrs, excess paint, or other obstructions that prevent free movement. (the three flat head screws holding the adjustment collar in place must be loosened first; a 0.9 mm hex screwdriver will loosen the screws)

To prevent the adjusting ring from accidentally moving, a small amount of damping grease can be added.

Replace the separated portion of the rotatable assembly and reinstall the washers in the reverse order of removal. After installing the washers, install the single jam nut in place of the nylon lock nut and adjust the preload applied by the bolt to your preference.

After the preload adjustment on the SV225 is complete, install the second lock nut and tighten it onto the first lock nut to prevent them from moving.

Replace the base plate that holds the bracket to the tripod and wipe all parts with a paper towel dampened with WD-40 to remove any excess damping grease.

Wear of gears or worms (unsmooth rotation, jumping or abnormal noise)

The plastic gears of low-end warp and latitude stations are prone to wear, and metal worms may rust or wear due to lack of lubrication.

Solutions

Plastic gears: remove the gears to clean the residue; apply silicone-based grease; replace directly if severely worn

Metal worms: remove rust with WD-40, lightly grind with fine sandpaper (600 mesh); apply special worm grease

How to prevent the warp and latitude station from loosening?

Regular maintenance

Check key screws every 3-6 months and add grease.

Balanced load

Make sure the center of gravity of the telescope is within the load-bearing range of the warp and latitude station to avoid excessive weight on one side.

Carry carefully

Remove heavy objects before carrying to avoid severe vibration.

Avoid over-adjustment

Do not forcefully turn a stuck warp and latitude station to avoid damaging the gears.

Conclusion

Loosening of the AZ-mount is a common problem, but in most cases we can be repaired with simple tools . You can refer to the repair process of the SV225 in the article. Has your azimuth telescope mount ever become loose? How did you solve it? Feel free to share your experience in the comments section!